Women’s Wear Daily

Automat Aims to Take Fashion Tech From Prototype to Production

BY AMANDA COSCO

This article was originally published by WWD on Wednesday, July 6th, 2016. View the original here.

Until now, the barrier for entry for creating fashion technology has been high. A designer must possess not only traditional cut-and-sew skills, but also the knowhow for integrating computer components into clothing.

Then there’s the software piece. Assuming a designer wants their garment to perform (read: work), they’d need to know how to code, which is about as easy as learning a new language. And all this was just to create a single concept piece — never mind the challenges of scaling and bringing one’s product to market.

With so many obstacles along the way, it’s no wonder most fashion designers have steered clear of wearables — and that many of the wearables on the market today lack a designer’s touch.

Fredrik Timour aims to change all that. He’s the chief executive officer of Neue Labs, the Scandinavian company responsible for Automat, a product created for enabling fashion tech. With toolkits shipping later this summer, Automat hopes to become the plug-and-play solution for the fashion industry, or for anyone who wants to get their hands dirty creating fashion tech without advanced programming skills. With Automat, a designer could swiftly be on the way to making connected clothing, like a dress that lights up when someone mentions you on Twitter, or a T-shirt with a printed xylophone on it that can actually be played.

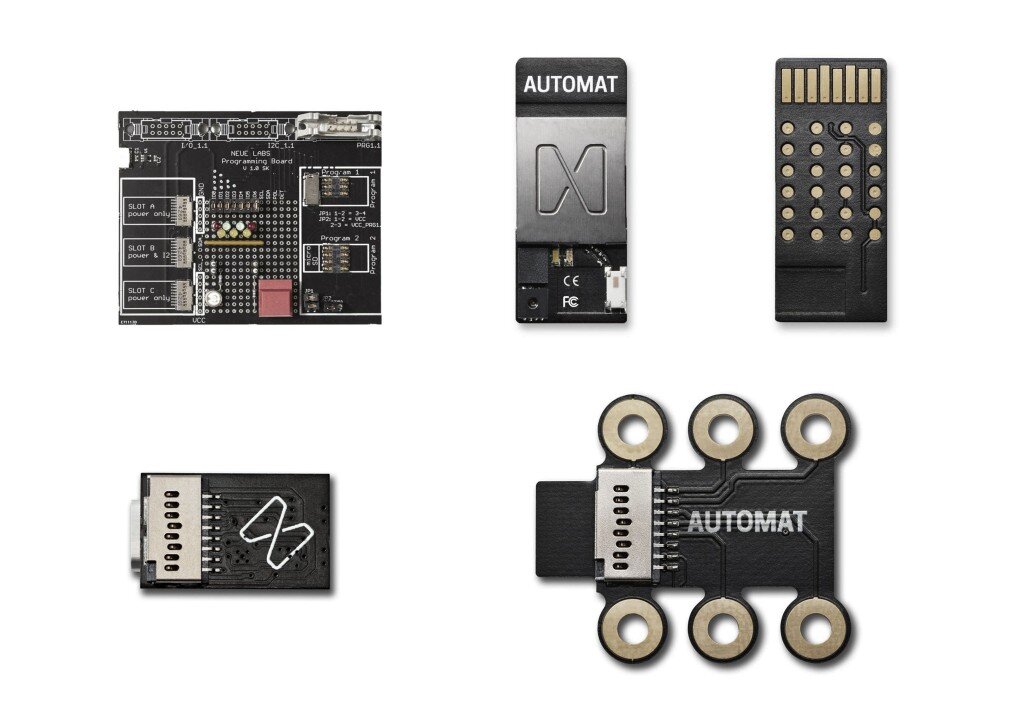

The Automat toolkit consists of a baseboard with high-quality sensors, a power board and a solder board. Twelve inputs and outputs connect to fabrics, buttons, lights and anything else a designer would want to connect to the Internet. The kit syncs with the Automat app, as well as an open-source SDK (for those who don’t speak geek, SDK is short for a software development kit — essentially a set of digital tools for creating apps).

“We’re targeting professional creatives,” Timour said over lunch in Stockholm, where Neue Labs is headquartered. Timour is in his 40s with bright blue eyes and dirty blonde hair. On a casual afternoon, he’s wearing a navy jacket and gray T-shirt and jeans. When asked how easy it would be for someone with zero programming skills to work with Automat, he likens it to learning any new specialized software. “Is it difficult to learn Photoshop? A little. Does it require you to know how to program? Not at all,” he said.

In addition to its ease of use, what differentiates Automat from other chips and sensors on the market is its small size. About a quarter of the size of Raspberry Pi or Intel’s Edison module, Automat is compact enough to fit into a piece of jewelry. What’s more, the toolkit is one of the only technology providers specifically targeting the fashion industry.

“We think fashion designers have specific needs and problems” Timour said. “At Neue Labs, we differentiate sports tech from fashion tech. Fashion designers approach clothing differently. It’s not always primarily about function.”

The distinction between sports and fashion tech is an important one. Since “wearables” became a buzzword a few years ago, any wristband with an accelerometer inside or shirt with sensors woven in has been lumped into the same category. As the market matures, it also diversifies. Today, the wearable technology category has been segmented into different but related subcategories, like wearables for sports and fitness, wearables for health and medical and fashion wearables (otherwise known as “fashion tech”).

While all of these segments may brush elbows, many look to the fashion industry to help beautify these devices and propel them into consumers’ everyday lives. Instead, what has sprung up are technology-led collaborations (think Apple Watch), or costume and concept pieces (think the Adrenaline Dress at New York Fashion Week). What’s really going to move the proverbial needle for fashion tech is when connected clothing can make the leap from the runway and onto store shelves. Closing this gap comes with its own set of challenges and requires new tools.

“We’ve been walking hand-in-hand with the fashion industry for a long time now,” Timour said. He cited H&M and Mulberry as examples of brands experimenting with Automat, although he couldn’t reveal any more details at the moment. “Right now, the industry is in a state of experimentation. Many brands are testing out pilot projects,” he said.

In addition to enabling designers, Neue Labs is interested in the data that Automat can gather for fashion brands. Sensors in shirts could tell a company how long their garments are being worn, or on which days they’re being worn. This data will inform everything from marketing to distribution. “We make the data anonymous, of course,” Timour added, anticipating privacy concerns.

While T-shirts tethered to the web sharing information about themselves may seem like the stuff of science fiction, it’s part of a larger trend toward connecting everyday objects to the Internet, also known as the Internet of Things (or IoT). The dream of the Internet of Things from a fashion perspective is clothing that enables consumers to seamlessly control and customize their environments and experiences. For example, a jacket that allows someone to adjust the volume of their music just by swiping their sleeve, or a pair of pants that can dim the lights in their living room with a tap of a finger.

While it’s fun to imagine the possibilities, Timour is much more focused on hitting that sweet spot between providing the hardware to deliver and the software to create, like the relationship between the iPhone and iTunes. He sees Automat as a foundation on which others can build. “I don’t think it’s interesting to speculate in terms of what people will create. I think it’s much more interesting to create the possibility to create,” he said.